THANK YOU FOR SUBSCRIBING

Food and Beverages Tech Review: Specials Magazine

When Fred Drake decided to improve how hot dogs were loaded into packages, he wasn’t working in a high-tech lab. It began in his garage with an innovative idea to optimize the only known autoloading solution. Forty-five years later, that same spirit of hands-on innovation and customer focus remains the heartbeat of Drake, a company known worldwide for delivering reliable, high-speed food loading solutions tailored to the unique needs of clients and world-class service and support. “In everything we do, from our legacy hot dog collators to the newest robotic integrations, we ask ourselves one thing, ‘What will help our customers the most?’” says Robyn Dean, president. Drake’s Legacy and Path to Growth Continuing this legacy of innovation, Drake evolved through family leadership and strategic mergers. In 2011, it became part of Middleby Corporation, further expanding its reach and capabilities. Consistently, the company’s core commitment has stayed the same—delivering custom-engineered food loading solutions as a trusted original equipment manufacturer in the food processing industry. Today, Drake’s food processors can be found worldwide, catering to a diverse international market. The core product lineup includes the original high-speed collator-style loader, designed for large customers requiring extremely high throughput and the capability to handle a variety of products. The company also offers a launcher-style loader, which is gentler and well-suited for softer products, alongside a new range of robotic solutions that can be paired with either a centrifugal bowl feeder or the traditional mechanical solutions. While the bowl feeder robotic system requires a large footprint, the collator-robot combination provides a powerful balance of speed and flexibility, capable of maintaining high output in a more compact space. The traditional collator and launcher loaders use a mechanical loading head, while the robotic systems use programmable robotic arms, offering greater flexibility in handling different product orientations and packaging styles. Custom-Engineered Solutions for Diverse Needs Drake’s client onboarding process is equally thorough. The company’s team conducts on-site assessments to understand the customer’s product characteristics, packaging dimensions, floor space, labor needs and throughput goals. This detailed data is used to develop a tailored solution with input from engineers and, if needed, the innovation group specializing in robotics and mechanical systems. In some cases, preliminary development can even begin prior to a formal order to ensure the solution fits the customer’s needs precisely. A recent example of overcoming a complex challenge involved a local customer with tight space constraints who needed to reduce labor by rotating their product 90 degrees before packaging. Drake provided a complete solution, combining a robotic arm with a collator system to achieve the required rotation, maintain throughput, reduce labor and fit the equipment into the limited space, demonstrating its commitment to problem-solving and customization.

Top Restaurant and Bar Inventory Management Software 2025

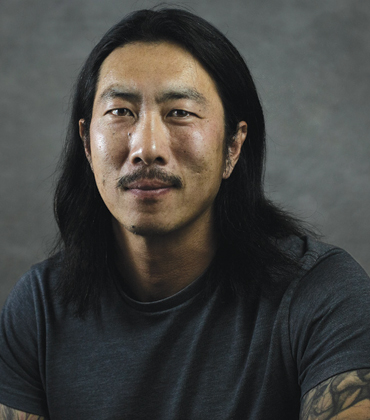

Every great cocktail tells a story, but the story behind the bar is often one of long hours, manual processes, and creative energy lost in spreadsheets. While guests enjoy seamless service, hospitality professionals juggle a chain of tasks—costing recipes, managing inventory, placing orders, training new staff, and reviewing performance metrics. What looks effortless to the customer can often feel chaotic to the people delivering the experience. This was the reality Dave Krysl and his team knew well. Having worked in bars and restaurants to put himself through college, Krysl later moved to New York City and fell in love with elevated cocktail culture. The creativity, community, and connection formed over food and drink inspired him. At the same time, he saw how difficult the job could be for those behind the scenes—and how often that difficulty kept them from the parts of the job they truly enjoyed. That understanding led to the creation of Spec, a hospitality operations platform designed to simplify the work that goes into running bars and restaurants. From recipe costing and inventory tracking to ordering, training, and reporting, Spec helps operators streamline their day-to-day tasks so they can spend more time focusing on creativity and guest experience—not just spreadsheets and back-office work. “Good food and beverage experiences bring people together. They shape a community’s identity and create spaces where people can connect,” says Krysl, founder and CEO. “But behind that experience, the day-to-day for workers is often unnecessarily hard. We wanted to change that.” Hospitality Tools That Actually Help Spec began as a simple mobile app bartenders could use to reference classic cocktail recipes—a time-saving training tool. But when the team shared it with bartenders in Nashville, the feedback was clear: what they really needed was a robust platform to store, customize, and share their own menus and recipes. That insight sparked the evolution of Spec into a full-fledged operational solution. Today, Spec helps hospitality teams manage recipes, cost analysis, inventory, ordering, training, and financial reporting. It was designed to eliminate redundancies—ensuring that one completed task can automatically support others. For example, adding a new cocktail recipe in Spec can instantly trigger cost calculations, update stock tracking, grant staff access to prep details, and support financial reporting..

Food Processing Solutions Provider

On a delightful Saturday morning, the facilities director of West Fargo Public Schools received an alert on his phone regarding a freezer malfunction at one of their campuses. It was a notification from TempLink’s monitoring system. Reading the message, the director realized there was a bulk order of ground beef, along with other inventory, stored in the freezer that had been shipped on the previous day for the school district. Upon checking, they found the freezer temperature was heating up due to an unknown failure and filled it with dry ice until the HVAC team arrived. The instant alarm activated by TempLink’s solution, composed of gateways, sensors, and a dashboard—saved all the food and inventory worth over $200,000. Sensors within the cooling unit detected the rise in temperature and communicated the issue to the dashboard via a gateway. Utilizing the reliability and scalability of Amazon Web Services (AWS) Cloud, the system promptly sent an alert from the dashboard to the director’s phone, ensuring they were immediately informed. TempLink integrates LoRaWAN technology into all its wireless sensors for better connectivity, eliminating common connectivity and range issues of Bluetooth and Wi-Fi-based systems. With its high-performance rating, LoRaWAN reduces power consumption, offers a longer range with less interference from other frequencies, and provides a more stable connection, scalability, and security. “Leveraging over three decades of combined experience, we have built high-sensitivity devices that offer superior connectivity, reliable monitoring, and a cost-effective solution for our customers,” says Gary Tharaldson II, CEO.

CXO INSIGHTS

Managing stakeholder demands in the Restaurant Tech Space

Jason Suarez, VP - Data Services, Digital and CRM Engineering, Platforms, Dine Brands Global

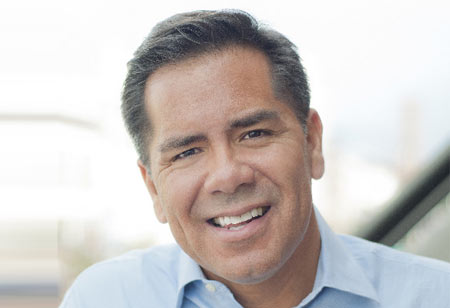

Top 3 Technology Innovations to Future-Ready Your QSR Brand

Rick Stanbridge, CIO Emeritus, Marco’s Pizza

From Bean to Bar: The Chocolate Journey at Barry Callebaut

Igor Annibal, Head of Sales - Food Service, Barry Callebaut

Proactively Welcoming the Food Evolution

Scott M. Danchise, Food Service Director, the Nutrition Group

Inventory Management and Strategic Planning

Larry Williams, Chief Supply Chain Officer, Biscuitville Fresh Southern

IN FOCUS

The Inventory Evolution Behind the Bar and Kitchen

Inventory management in restaurants and bars has transformed from manual processes to automated, data-driven systems, enhancing efficiency, profitability, and guest satisfaction through real-time tracking and analytics.

EDITORIAL

Technology Driving the Future of Dining

Mechanical and robotic food handling equipment is moving rapidly from experimentation to mainstream adoption. Robotic arms capable of precision plating, automated fryers ensuring uniform results, and bartender robots mixing cocktails are redefining speed and accuracy in foodservice. These solutions reduce the risks of human error, enhance hygiene, and alleviate labor-intensive tasks, enabling staff to focus on higher-value areas of service and creativity. As consumer expectations for consistency and safety rise, robotics provides reliable answers that align with both operational goals and guest satisfaction.

Parallel to this shift, restaurant and bar inventory management software is transforming supply oversight. Traditional stocktaking, long plagued by inaccuracies and delays, is now being replaced by real-time data platforms. These systems track ingredient usage, forecast demand, and integrate seamlessly with suppliers to streamline replenishment. In bars, especially, where shrinkage and spillage can significantly affect margins, digital monitoring introduces a new level of accountability and precision. The result is reduced waste, optimized costs, and a more sustainable supply chain.

Robotic systems generate consistent output data, while inventory management platforms analyze and act upon it. This closed-loop ecosystem enhances efficiency, minimizes waste, and ensures businesses remain agile in a competitive environment. By integrating robotics on the floor and intelligent software in the back office, the food and beverage sector is adapting to challenges and defining the next chapter of dining.

This edition highlights the expert perspectives of Larry Williams, Chief Supply Chain Officer at Biscuitville Fresh Southern and Scott M. Danchise, Food Service Director, The Nutrition Group. These esteemed professionals share their invaluable insights on the developments and challenges within the sector, along with possible solutions.

We hope these valuable insights from industry leaders featured in this edition will assist you in making informed decisions for your businesses.