THANK YOU FOR SUBSCRIBING

Food and Beverages Tech Review: Specials Magazine

Recently, a friend asked me about a food safety recall. It had been in the news that people had died, and she was concerned for herself and her family. Her daughter loves a particular food, but she has not been buying any for fear it would make them ill. Her fear is understandable, as, according to the World Health Organization, an estimated 600 million people suffer from foodborne illnesses, and approximately 420,000 deaths are attributed to foodborne illnesses every year. Proper traceability and effective recalls are essential for protecting consumers against foodborne illnesses. Recalls can, however, have unintended and far-reaching consequences. Consumer trust is a cornerstone of the food industry, and recalls can significantly erode this trust, prompting shifts in consumer behavior. The complexity of modern food supply chains often leaves consumers unable to discern between safe and unsafe products. Consequently, a consumer may avoid all similar products out of caution, regardless of origin. This ripple effect extends to manufacturers in the supply chain, who may seek alternatives to the impacted foods to avert potential rejection by consumers. The panic and erosion of trust stemming from a food safety recall can lead to intense competition and market saturation. Suppliers of short-shelf-life products, such as fresh produce, face substantial financial losses as they struggle to sell products before expiration. Disposing of large quantities of unusable or unsellable items further adds to these financial setbacks, and smaller growers may find it challenging to weather such economic storms. Some industry members advocate for enhanced messaging and consumer education to mitigate the negative impact on consumer perception post-recall. Providing consumers with detailed information about the recall, including images of affected brands, names of affected stores, and the recall's effectiveness, could enhance consumer confidence. Regulators, retailers, and manufacture

Top Automated Baking Equipment Manufacturer in Canada 2025

Skilled bakers score artisan bread precisely to help the dough rise and create perfect patterns. Imagine that same precision executed at 600 cuts a minute. That is the world ABI has built over 35 years, where robots boost the human touch in baking, not replace it. ABI began as a small family business making bagels and has grown to lead in robotics for baking automation. ABI’s success isn’t just about high-tech gear. It understands that good automation starts with thinking like a baker, not an engineer. This is evident in its emphasis on people, who are essential to delivering great customer service. “Our employees have expansive experience within the organization, which translates into how they take care of the customer,” says Alyson Slapkauskas, CEO. This mindset shapes everything ABI does, from the demo room where clients test ingredients with ABI’s machines to its 25-year equipment support. ABI cultivates teamwork that goes beyond just doing business. The Art and Science of Baking At the heart of ABI’s innovation lies Katana Robotic Scoring System, its vision-guided robotic scoring system that maps each dough piece in real time and adjusts the tool path so every cut lands in the right place, at high speed and with repeatable precision. The system’s versatility is remarkable. It quickly switches between tools like drag blades, plunge blades, water jet and conventional blades, handling different products and patterns. For the highest production speed, Katana Robotic scoring system comes with a waterjet tool, which can make up to 600 cuts every minute, in a consistent manner that hand scoring cannot match. Alongside the Katana Robotic Scoring system, ABI’s pick-and-place equipment uses smart vision to detect and position items on conveyors or baking pans. It also works well with delicate dough and pastries thanks to the various end of arm tools (EOAT) available, reducing damage and improving speed and versatility. This automated setup tackles tricky manufacturing while boosting accuracy and output.

Top Food Processing Solutions Provider

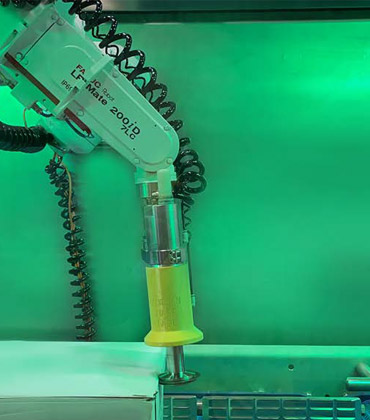

MHM Automation is a global leader in the provision of automated product handling solutions to the food industry. The company offers industry-leading technologies in reverse packaging systems for secondary dairy and meat processors, large-scale automated box chilling and freezing systems for meat and dairy processors, and packaging systems. Its real strength lies in the ability to deliver integrated solutions that are customdesigned and developed to meet each food processor’s needs. “We have delivered more than 1000 installations for food processors worldwide, including many of the world’s biggest names in meat and dairy,” says Richard Rookes, the CEO of MHM Automation. MHM Automation prioritizes establishing strong connections with its customers. With an extensive range of systems, products, and services, the company offers exceptional solutions for its customers' facilities. Since MHM Automation often works with existing sites, it has the capability to design and deliver customized solutions that not only achieve the desired outcome but also fit seamlessly into the available space. For example, MHM Automation provided a completely automated reverse packaging system for a cheese converter in the U.S. It delivered an integrated system to completely automate the process of taking 40lb blocks of cheese from the pallet to the production line, naked and ready for processing. This system was designed, manufactured, installed, and integrated with the rest of the existing production line. Subsequent to the initial installation, additions have been made to further automate processes. An automatic batching process separated the 12 types of cheese being produced and stacked them into totes or sent to the production line. MHM Automation also delivered an automated, operator-free solution for raw block palletizing, which included the development of a custom grip head to protect the product and ensure that the client adhered to the strictest hygiene standards. In another example, MHM Automation helped a leading meat processing company in the U.S. increase production capacity, improve operational equipment effectiveness, streamline processing methods, and reduce product damage. Reliance on manual labor was preventing the plant from achieving maximum outputs. The company provided an integrated solution to address this issue. The solution included a robotic de-palletizer that automatically depalletizes frozen meat box pallets and a Universal Robotic Box Cutter (UBC) with a box size recognition vision camera allowing for multiple box size and type cutting. MHM Automation also provided a side tip de-boxer module tipping the contents onto a cushioned flight conveyor, which feeds the jumb

Food Processing Solution

The future of food production is seamless, intelligent and sustainable, and Fortifi is leading the transformation. With a full-lifecycle approach to automation, it integrates robotics, AI-driven machinery and advanced software to optimize every stage of food processing. From farm-fresh ingredients to packaged perfection, Fortifi ensures speed, quality and resource efficiency. Its singular focus on food solutions sets it apart from other providers, offering a global presence in every aspect of automated food processing. It delivers all the essential components and ensures they work together seamlessly to drive efficiency and innovation in food production. Fortifi approaches food processing automation from a 360° perspective, identifying early-phase needs, designing entire plants, supplying machinery and tools, installing and commissioning production lines, providing field service and retrofitting existing systems. Taking full ownership of automation processes, it enables food producers to optimize their operations while maintaining high levels of safety, precision and quality control. Its expertise spans red meat, poultry, dairy, seafood and produce, understanding the distinct challenges of each sector. “We understand the importance of responsive customer service, innovation and high-quality solutions in helping our customers achieve their operational goals,” says Massimo Bizzi, CEO. As food producers face mounting pressures to increase output while minimizing waste, labor shortages and rising operational costs, automation is no longer a luxury—it is a necessity. Fortifi’s solutions streamline production lines, reducing manual labor, improving workplace safety and increasing overall efficiency. Integrating intelligent packaging, sorting and food handling technologies, it maximizes yield while minimizing waste and environmental impact. Optimized food processing not only

CXO INSIGHTS

Optimizing Supply Chain Resilience

Keefer Gibson, Sourcing Manager in Supply Chain, Bimbo Canada

Safeguarding Quality and Safety in the World of Nutritional Beverages

Guillaume Couture, Quality Assurance Manager, Kerry Inc

Integrating Sustainability: Strategies for Corporate Success

Lynessa Darko, Sustainability Manager, Diageo

Adventures in the Dairy Industry: From Cheese Making to Sales Manager in Saudi Arabia

Michael Jul Pedersen, Production and Technology Development Manager, Arla Foods

Ensuring Smooth Supply Chain Operations

Ilana Fridman, Supply Chain Planning Manager, The Hain Celestial Group

Logistical Challenges Facing the Meat Industry with Fluctuating Demand

Kayla Baurenschmidt, Director - Supply Chain, Exceldor, coopérative avicole

Transformative Technology in the Hog Industry: A Look Back Since 2003

Darrin Duell, Director of Risk Management and Continuous Improvement, Olymel

IN FOCUS

Automation's Role in Meeting Canada's National Demand for Baked Goods

Automated baking in Canada enhances consistency, quality, and efficiency, transforming traditional methods into precise and innovative processes that meet the national demand for baked goods.

Government-Fueled Automation in Canadian Bakeries

Canada's bakery sector is modernizing through automation and digital integration, driven by labor shortages and government support, enhancing efficiency and global competitiveness while prioritizing sustainability.

EDITORIAL

Automation and Agility Shaping the Future of Food Production

The food manufacturing industry is entering a new era where automation and human expertise work together to redefine consistency, quality, and efficiency. Across Canada and beyond, technology is becoming an essential partner in kitchens, factories, and production floors, driving precision and innovation at every stage of the process. In this edition of Food and Beverage Tech Review Canada, we explore how advanced automation is reshaping the future of food production. From robotics that handle delicate pastries to intelligent systems that ensure perfect dough texture, automation is not replacing craftsmanship but elevating it. Behind every system and sensor is a philosophy built on understanding the art of food creation as much as the science that powers it. Automated baking technology represents one of the clearest examples of this transformation. The new generation of systems combines vision-guided robotics, real-time feedback, and adaptive cutting and handling to achieve precision that once relied solely on experience. These solutions are designed not just for speed but for balance. They integrate seamlessly into existing operations, reduce waste, and support consistent product quality while preserving the creativity and skill that define artisan production. What makes this evolution remarkable is the focus on people, ensuring that technology complements craftsmanship rather than replaces it. Also featured in this issue, Darrin Duell, Director of Risk Management and Continuous Improvement at Olymel, reflects on how technology and automation have transformed the hog industry into a more data-driven and sustainable ecosystem. Ilana Fridman, Supply Chain Planning Manager at The Hain Celestial Group, offers insight into managing complexity in modern food supply chains through collaboration, adaptability, and smart planning. Together these perspectives illustrate how technology can enhance precision, efficiency, and sustainability without losing sight of the human touch that defines great food. The future of food production belongs to those who can combine innovation with intuition and automation with artistry.